Board Manufacturing

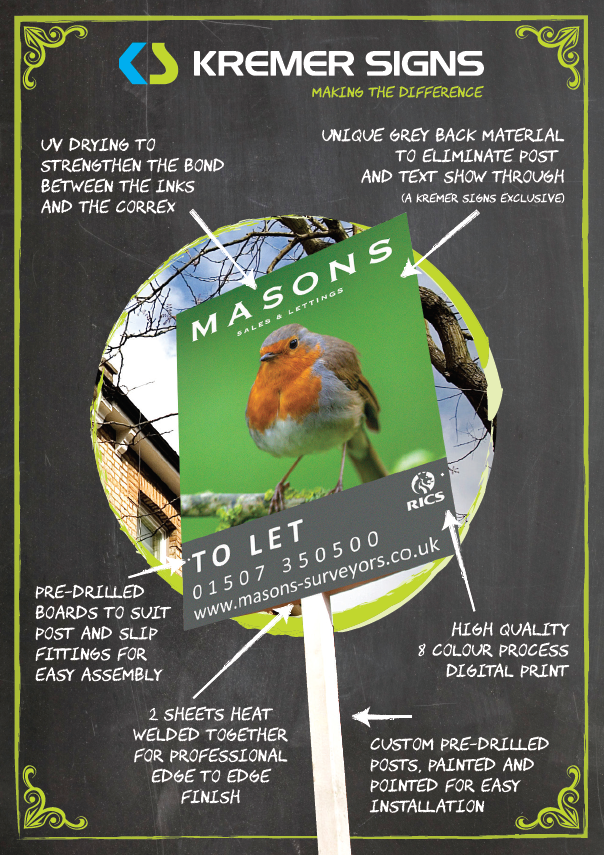

With our 4 state of the art INCA Spyder printers we can produce the highest quality estate agency boards on the market. Prior to print we prime all of our correx material to ensure a strong bond between the inks and the material. After print, we then run the boards through a UV drying process which increase the board’s durability dramatically, which in turn will result in a better life expectancy of your signage.

For T Boards, we heat-weld the two sheets together to create the opening down the middle for the posts, which forms a bond between the two sheets that cannot be pulled apart, which is far more superior to double sided tapes, as these can prove to become brittle whilst exposed to colder temperatures.

We have an on-site drilling and guillotine bench which insures all of the boards, slips and posts correspond exactly with each other, making the assembly of the boards effortless. For all orders we keep behind a template board to ensure the same colours are replicated on future orders and that drilling also matches up so that there are no discrepancies further on down the line.

For boards with a predominantly white design, we use our exclusive ‘grey back’ correx sheet material that has a pure white face with a dense grey back, which when the two sheets are heat welded together, totally blocks any show through of the post erected through the middle, even in the strongest sunlight. This is a problem that many agents face that have white board designs, which can make the boards look cheap, and in some cases make the text hard to read, when a shadow is casted vertically through the board due to the stake. Another major benefit is that the new correx, the heaviest in the marketplace at 700gsm, is made from fully recycled materials making it not only the best quality agency board on the market, but also the most environmentally friendly.